The future is already behind us. Or inside?

The future is already behind us. Or inside?

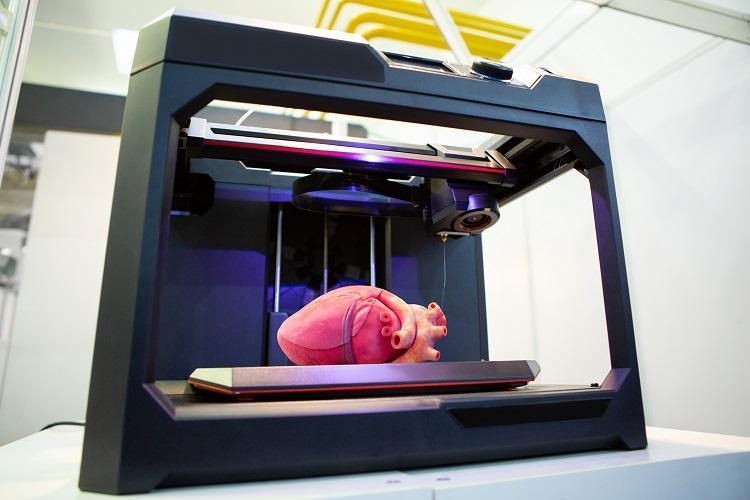

This is a wide spectrum article that covers all aspects of 3D manufacturing technology, including biological tissues, organs and cells for medical and biotechnological applications. Topics include nanomaterials, biomaterials, frameworks, 3D printing technologies, software and hardware for image processing and CAD / CAM, the ripening of the bioreactor after printing, modeling cells and biological factors, biofabrication, tissue engineering and other aspects of 3D-bioprinting technology.

Production technology

3D-bope technology for the manufacture of biological structures, as a rule, implies the placement of cells on a biocompatible basis using a layer-by-layer method of generating three-dimensional structures of biological tissues. Since the fabrics in the body consist of different types of cells, the technologies of their production by the 3D-bio-printed method also differ in their ability to ensure the stability and viability of cells. Some of the methods that are used in 3D boperates are photolithography, magnetic biofer, stereolithography and direct cell extrusion. Cellular material made on a bioprinter is transferred to an incubator, which is subjected to further cultivation.

Integration

According to expert estimates, the American company Organovo, located in San Diego, has become the first company commercializing 3D-bio-printed technology. The company uses 3D bioprinters NOVOGEN MMX BIOPRINTER. 3D printers used by Organovo are designed for the manufacture of:

- skin

- heart

- blood vessels

- other fabrics that can be suitable for surgery and transplantation.

A research team from the University of Swansea in the UK uses 3D-bope technologies to create soft tissues and artificial bones for possible use in reconstructive surgery.

One of the most impressive demonstrations of 3D-bope technologies took place in 2011, when at the TED-2011 conference, a special 3D printer printed a mock of human kidney directly during the performance of the American surgeon and Bioingenger Anthony Atala.

In 2017, in China, the ears printed on the 3D printer were transferred to children with an innate ear defect.

In the field of gastronomy in Russia, 3D bioprinter technologies were used by the chefs Anatoly and Ivan Berezutski.

Meaning for humans

The development of 3D-biopite technology plays an important role in the cultivation of organs and the development of innovative materials, primarily biomaterials - materials prepared and used for printing three-dimensional objects. Fabrics, medicines (in the future, entire organs) made by 3D-bioprinting, in the future will be able to act as substitutes for "natural'' human organs, in some cases possessing properties that are superior to natural organs. For example, the production of alginic acid, currently extracted from red algae and superior in a number of parameters natural "material" of the human body, and the production of synthetic hydrogels, including polyethylene glycol-based gels.

In Russia, a private laboratory operating in the field of three-dimensional bope of organs, 3D decisions for biopratek, announced the results of an experiment on the transplantation of the mouse of the thyroid construct, printed using the Russian Fabion bioprinter. Over the next few months, "the designs were rooted and proved their viability." And in December 2018, Russian specialists managed to obtain the first results of an experiment on the press of organs on the ISS: the bioprinter printed the design of the thyroid gland and the cartilage tissue of a person in conditions of weightlessness.

Be the first to post a message!